By Michael Lauzon

CORRESPONDENT

Published: November 19, 2014 3:30 pm ET

Updated: November 19, 2014 3:38 pm ET

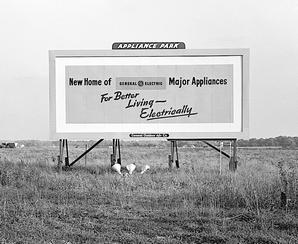

Image By: GE Appliances

During the past 25 years, GE has cut production at its U.S. Appliance Park in Kentucky, then began investing heavily in new production there as it reshored production.

Changing global trade patterns, a maturing market, environmental concerns and innovation were all key forces that have shaped the appliance sector in the past 25 years.

A game-changer for the industry was the North American Free Trade Agreement. The United States and Canada began implementing a trade agreement in 1989, and Mexico joined NAFTA in 1994.

With trade barriers knocked down, Mexico became a more desirable place for producing appliances because of its low-wage environment. Electrolux AB, for example, one of the top three appliance majors, located large factories in Mexico as part of a multi-year drive to produce white goods in lower-cost regions.

The growth of appliance manufacturing in Mexico spurred numerous plastics processors to locate production in the area in the early 1990s to more easily supply the appliance manufacturers and other local customers, as well as to take advantage of low costs to supply original equipment manufacturers assembling in the United States. Processors flocked to the border area, including El Paso, Texas.

Appliance manufacturers and their suppliers also looked elsewhere for high growth and low-cost manufacturing opportunities because North America’s appliance market was rapidly reaching maturation.

North American appliance production peaked in the mid-2000s. U.S. shipments rose from $16 billion in value in 1992 to $23.3 billion in 2007, according to data from the U.S. Census Bureau. Then the U.S. housing and banking crises hit and put a crimp in demand and shipments. It took a few years for U.S. appliance markets to grow again. U.S. shipments reached about $20 billion in 2013 and by 2014 were running at about $21 billion.

Appliance shipments roughly track new housing construction and retrofits for existing homes. In the U.S. and Canada, appliance markets are mature since product penetration among consumers is very high. For example, in the United States and Canada, about 90 percent of households have free-standing ranges and about 100 percent have refrigerators. Therefore appliance shipments in North America rely heavily on the replacement market.

Energy savings

Appliance OEMs help fuel the replacement market with appliances with better energy profiles and new features. Some clothes washers are up to 150 percent more energy efficient than in the early 2000s and use 40 percent less water. OEMs have introduced numerous major appliances that meet Energy Star ratings designed by the U.S. Department of Energy and the U.S. Environmental Protection Agency. Features such as front-loading washers and advanced, user-friendly controls also help fuel sales.

Most global appliance growth is occurring in developing countries where market penetration is low. As citizens of developing countries improve their standards of living, they are buying kitchen ranges, laundry appliances, microwave ovens and air conditioners. Much of the demand is met by domestic producers, but imports also are important sources.

Locating production in developing countries does have drawbacks, however. Supply lines and response times are long. Parent companies lose some control over quality. And transplants might not get protections afforded to the domestic producers.

GE Appliances is one OEM that decided U.S.-based production makes more sense. In the past few years it has been repatriating production from China and Mexico. GE said in 2011 it would invest $1 billion in its appliance business to modernize and upgrade to make new products. The decision followed a strategy three years earlier in which it tried to divest the appliance business but recessionary pressures dissuaded potential suitors from meeting GE’s sale price. In 2012, GE also said it would make a lot more of its plastic components in-house at its large Louisville, Ky., complex.

Image By: GE Appliances

GE recently marked the 60th anniversary of its Appliance Park manufacturing facility.

GE, which has been making appliances since 1907, recently signaled it wants again to try to sell its appliance stake after it investing heavily to make it a more attractive business. Appliances are a tiny fraction of GE’s business — appliances and lighting sales were about $8 billion in 2013, or 5.6 percent of total sales — which is dominated by its financial services and heavy engineering. In summer 2014, Electrolux confirmed it was talking to GE about a potential sale. Electrolux, with 2013 sales of $15.9 billion, is about twice the size of GE Appliances.

GE is not the only conglomerate questioning how to be involved in a maturing appliance market. Siemens AG has agreed to sell its stake in Bosch und Siemens Hausgeräte GmbH, a diverse appliance producer better known as BSH or Bosch, to partner Robert Bosch GmbH. BSH factories are concentrated in Germany, although the venture runs 41 plants worldwide. In the United States, BSH has plants in New Bern, N.C., and LaFollette, Tenn. BSH does in-house injection molding and thermoforming and also buys components from outside suppliers. It logged sales of $13.3 billion in 2013.

Siemens decided to sell its stake as “part of our drive to continue focusing very intensively on our core business,” Siemens CFO Ralf Thomas explained in September. The diverse firm’s main markets include automation, construction, power drives, energy, healthcare and financial services. Completion of the sale is expected in the first half of 2015.

Whirlpool Corp., unlike competitors GE and the BSH partners, is a “pure play” appliance manufacturer undistracted by other businesses. As the largest appliance maker in the world since 2006 when it bought Maytag Corp., it is unusual in that it does most of its production in the United States. At eight facilities it employs about 14,000, with Ohio having the greatest concentration of plants and employees. It too looks for efficiencies and to that end it has frequently moved production around the United States.

Relocation of appliance manufacturing to lower cost regions has spawned unofficial and official trade barriers as manufacturers and governments try to protect their domestic industries. Notable were dumping investigations regarding imports into the United States from Mexico and South Korea initiated by Whirlpool in 2011.

Plastic content

Plastics are a major input to appliance manufacturing. A side-by-side refrigerator, for example, contains about 90 pounds of plastics. Polyurethane insulation in the refrigerator weighs about 25 pounds and the rest is divided among liners, shelves and drawers made of polystyrene, ABS, PVC, acetal, nylon and other resins.

Given the plastics content of appliances, it is no surprise a lot of processors are attracted to the market. Although appliance manufacturers do some plastics processing in house, they rely on many outside suppliers that injection mold, extrude and thermoform various components. OEMs do urethane insulation foaming in-house because doing it in-line is most productive. Appliance OEMs are always looking to cut costs and this puts pressure on parts suppliers to keep their costs down. It is not uncommon for OEMs to switch suppliers for cost, quality or other reasons.

Supplying appliance OEMs is a competitive and occasionally risky business. The potential pitfalls were illustrated by the fate of one of the former major appliance suppliers in the United States, Moll Industries Inc. Moll had a financially troubled history but it really ran into trouble in 2006 when Whirlpool pulled business worth two thirds of Moll’s sales. The cutback led to Moll spiraling into bankruptcy in 2010.

Like other industries, environmental issues began demanding serious attention in the appliance industry beginning in the 1980s. Energy efficiency and ozone-depleting potential of blowing agents have been major issues driving plastics use in appliances. Energy efficiency has been improved by replacing steel refrigerator liners with those made from ABS and PS. Tweaking urethane foam formulations and blowing agents have also improved energy usage.

Image By: GE Appliances

GE says reshoring production has allowed it to tweak products for American lifestyles, such as special fittings for water bottles in its dishwashers.

Lowering the ozone-depleting potential and greenhouse warming potential of urethane blowing agents have been major research efforts, especially regarding refrigerators and freezers. Ozone concerns had been on the table for years — in 1987 the Montreal Protocol agreement was signed to protect the ozone layer in the upper atmosphere — but addressing them presented vexatious problems.

In 1996, a major milestone for ozone protection was achieved with the phase-out of R11 blowing agent, according to Bayer MaterialScience LLC, a key supplier of urethane foaming systems. By 2017, other ozone-depleting blowing agents will be phased out. Blowing agents of choice in North America likely will be cyclopentane and new agents based on hydrochlorofluoro-olefins. In the latter category Honeywell International Inc. debuted its Solstice HFO-1233zd, a blowing agent it claims has low global warming potential. The U.S. Environmental Protection Agency approved Solstice for urethane foam in 2012 and two years later Whirlpool became the first major appliance firm to commercially use it. Whirlpool uses Solstice in new urethane technology developed by BASF Corp.

Innovations and new features are continually introduced by appliance OEMs to try to stimulate purchasing in a mature market. Energy efficiency improvements are attractive to consumers and to government agencies. U.S. government rebates a few years ago encouraged consumers to invest in the more efficient appliances and get rid of older models. The rebates helped U.S. appliance sales in the 2010 to 2012 period, although the stimulus was partly offset by sluggish housing activity.

Efforts to improve product sustainability is another greening trend in the industry. Sustainability standards are being introduced by the Association of Home Appliance Manufacturers in conjunction with CSA and UL. AHAM and its partners developed a points system that rates an appliance on a life cycle basis. One of the criteria addresses hazardous materials. Appliance OEMs have been reducing or eliminating such chemicals as halogenated flame retardants and lead and other heavy metals. Refrigerator and freezer sustainability standards published in 2012 were AHAM’s first but it has since been expanding the program to other major and small appliances.

North America’s appliance industry has matured in the past 25 years, but the future is bound to hold surprises. Mergers and acquisitions are overdue in a crowded, competitive market. OEMs will continue to fiercely look for cost cuts. And ruling over all is the industry’s capacity to innovate to create and meet new consumer demands. |